Oct 9

Getting the Terms Straight: SWL, WLL and Design Load

On every ship you’ll see lifting gear, cranes, mooring winches and lines marked with safe-load figures.

Yet those familiar letters — SWL, WLL, and Design Load — are often mixed up.

Understanding them correctly is essential for safe deck operations.

Yet those familiar letters — SWL, WLL, and Design Load — are often mixed up.

Understanding them correctly is essential for safe deck operations.

Safe Working Load (SWL)

Under the Code of Safe Working Practices for Merchant Seafarers, the Safe Working Load is the maximum load that lifting equipment can safely handle in service.

It’s determined by dividing the item’s breaking load by a factor of safety. A shackle, crane, or derrick tested to a proof load well above its SWL is then certified for normal use at or below that figure.

It’s determined by dividing the item’s breaking load by a factor of safety. A shackle, crane, or derrick tested to a proof load well above its SWL is then certified for normal use at or below that figure.

Think of SWL as the “do-not-exceed” limit for day-to-day operations — the load under which the equipment will work indefinitely without distortion or failure.

Working Load Limit (WLL)

The Working Load Limit is the modern, internationally standard term used by manufacturers. It represents the maximum load that a piece of equipment or rope is designed to carry under normal service conditions, including an in-built safety factor.

While SWL is set by a competent person through testing and examination, WLL is fixed by the manufacturer during design certification. Functionally, both serve the same purpose — the highest permissible operational load.

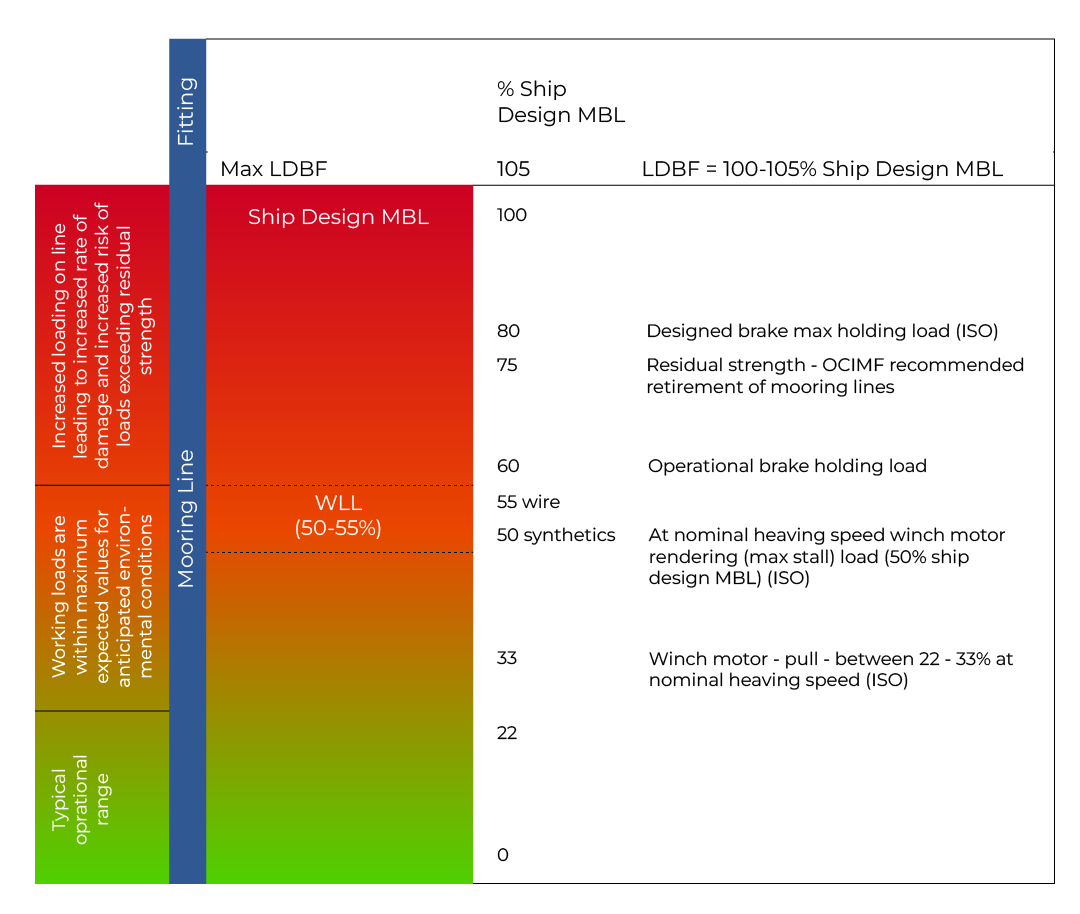

In the mooring context, MEG 4 defines WLL as the maximum load that a mooring line should experience in service, expressed as a percentage of the ship’s design MBL. Steel-wire ropes use 55 %, synthetic ropes 50 %, of the ship design MBL.

Design Load and the Mooring Terminology

Design Load takes us back to the drawing board — the engineering basis on which all safe limits are built. MEG 4 sets out four linked definitions that show how mooring-system strength is established:

- Ship Design Minimum Breaking Load (MBL) – the breaking strength of new, dry mooring lines for which the ship’s mooring system is designed. It is the reference value against which every fitting, winch, and line is sized.

- Line Design Break Force (LDBF) – the certified breaking force of a new spliced line as declared by the manufacturer, normally 100 – 105 % of the ship design MBL.

- Working Load Limit (WLL) – the in-service operational limit, normally 50–55 % of the ship design MBL. Exceeding it risks accelerated fatigue and failure.

- Design Basis Load (DBL) – the load applied to deck fittings and winches when calculating their required strength, obtained by multiplying the ship design MBL by a geometric factor (GF) to account for lead angles and load distribution.

The coloured chart visualises this relationship.

- The green zone (below WLL) represents safe, typical operational loads.

- The amber zone (between WLL and ship design MBL) covers the upper design envelope.

- The red zone (beyond 100 – 105 %) shows loads approaching the Line Design Break Force where structural damage or line parting becomes likely.

Why It Matters

In practice, Design Load defines what the system can take, while SWL or WLL define what you should actually use.

Staying within those limits prevents excessive stress, fatigue, and catastrophic failure.

For the Officer of the Watch, recognising these markings isn’t paperwork — it’s seamanship.

Respecting them keeps the ship, the equipment, and your crew safe every time a load is lifted or a line is tensioned.

(References: COSWP Ch. 19; MGN 332 (M+F) Amendment 3; OCIMF Mooring Equipment Guidelines 4th Edition, Sections 5.2 & 5.2.4, Figures 1.3 and 5.2.)

Staying within those limits prevents excessive stress, fatigue, and catastrophic failure.

For the Officer of the Watch, recognising these markings isn’t paperwork — it’s seamanship.

Respecting them keeps the ship, the equipment, and your crew safe every time a load is lifted or a line is tensioned.

(References: COSWP Ch. 19; MGN 332 (M+F) Amendment 3; OCIMF Mooring Equipment Guidelines 4th Edition, Sections 5.2 & 5.2.4, Figures 1.3 and 5.2.)

Onboard Maritime

Contact Us

+44 (0) 344 090 3004

info@onboardmaritime.com

info@onboardmaritime.com